By Ivan Pak, Chief Technology/Business Officer of International ePaper Technology Corp.

In recent years, the adoption of Electronic Shelf Labels (ESLs) has accelerated across the retail landscape, driven by the need for operational efficiency, price accuracy, and the promise of long-term cost savings. From major grocery chains to specialized retailers, businesses are turning to ESL technology as a critical tool for digital transformation. While many retailers begin their analysis of ESL investment from a product cost or software integration standpoint, a recurring oversight in the return on investment (ROI) evaluation process is the financial and functional impact of mounting solutions. These accessories—seemingly minor compared to the ESL devices themselves—are in fact a pivotal component in both the initial capital outlay and the long-term maintenance strategy. Ignoring their contribution to total cost of ownership can lead to inaccurate ROI projections and unpleasant surprises down the road.

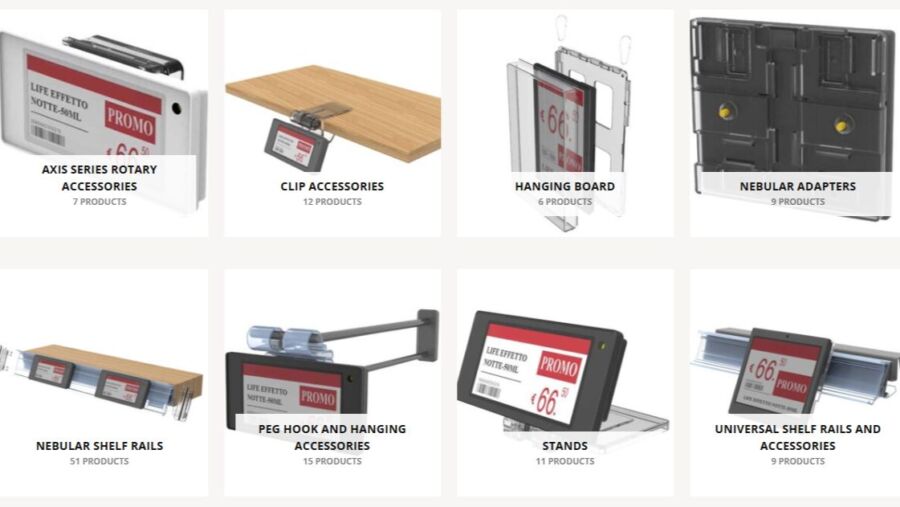

A recent industry study has indicated that mounting solutions may account for as much as 12% of the total cost of ESL implementation. This figure often catches retailers off guard, especially those who focus exclusively on unit pricing or vendor discounts when budgeting for ESL systems. The reality is that mounting accessories, including rails, brackets, adapters, clips, and spacers, are not only necessary for deployment—they are essential for ensuring the stability, durability, and operational viability of the entire ESL ecosystem. Poorly selected or cheaply manufactured mounts can lead to label misalignment, product obstruction, accidental detachment, and ultimately, costly replacements or customer dissatisfaction. Therefore, incorporating mounting accessories into a comprehensive ROI analysis is not optional; it is critical.

When retailers assess ESL deployment, the instinct is often to prioritize the ESL display features, battery life, or communication protocols. While these are certainly important, mounting solutions deserve equal attention because they serve as the physical foundation upon which ESL functionality depends. A high-end ESL installed with subpar mounting solutions is analogous to installing a state-of-the-art screen on a cracked wall—it simply won’t perform to its potential. Moreover, unlike the ESLs themselves, which are designed to last between five and ten years with relatively minimal maintenance, mounting solutions are subject to frequent stress from restocking, customer traffic, and environmental factors such as cold storage conditions. In fact, data from various field deployments have shown that ESLs placed on bottom shelves or freezer doors experience accessory damage rates as high as 20%, primarily due to mounting system weaknesses. Such incidents can drastically increase long-term costs if preventive measures are not taken at the outset.

A key aspect of maximizing ESL ROI is understanding the correlation between mounting quality and labor costs. Retailers frequently underestimate the time and effort it takes to re-secure or replace faulty mounts. In environments where staff availability is limited or high turnover is prevalent, the burden of maintaining ESL hardware falls on a smaller operational team, increasing the risk of lapses in shelf accuracy or ESL downtime. On the other hand, investing in high-quality mounting solutions reduces the need for routine adjustments or replacements, thereby saving valuable labor hours that can be redirected to customer service or inventory management. In effect, better mounting solutions directly contribute to productivity gains and better store performance—two major levers in the ROI calculation.

Material selection also plays a crucial role. Not all mounts are made equal. ESLs used in refrigerated sections, for example, require accessories made of special materials that resist condensation and maintain grip in low temperatures. Similarly, for stores with metal shelving or curved edges, mounts must offer specific compatibility and flexibility without compromising structural integrity. Choosing a vendor that supplies EP (E-Paper) certified accessories—engineered specifically for ESL systems—is a wise move that ensures the accessory lifecycle matches the expected ESL lifespan. These accessories are tested for endurance, alignment precision, and environmental resistance, which collectively enhance ESL performance and reduce maintenance costs.

Craftsmanship is another determinant of long-term value. Mass-produced, low-cost mounts often lack uniformity, leading to misalignment issues that not only disrupt the visual presentation of ESLs but can also cause functional errors in barcode or price scanning. In high-volume retail settings, this kind of inconsistency can ripple into customer dissatisfaction, pricing errors, and operational inefficiencies. Conversely, well-crafted mounting systems allow for precise, stable placement of labels, reducing wear and tear and upholding brand presentation standards. Over a multi-year ESL deployment cycle, these quality differences translate into tangible cost savings.

Another overlooked factor in ESL ROI related to mounting systems is scalability. For multi-location rollouts, standardized, easy-to-install mounting solutions make a significant difference in deployment speed and cost. When each store follows a consistent mounting framework, staff training, installation time, and post-installation support all become more efficient. A scalable solution allows corporate teams to plan more predictable capex budgets and reduces the burden on field service teams. Furthermore, in cases of store renovations or product reorganization, reusable and modular mounting systems allow ESLs to be reinstalled or repositioned without purchasing new mounts. This flexibility protects the original investment and enables agile store design changes—an increasingly important feature in today’s rapidly evolving retail environment.

Sustainability is also becoming a growing priority in ROI discussions. Recyclable or reusable mounting systems contribute to a retailer’s environmental goals and can even be part of ESG reporting. High-quality accessories made with sustainable materials reduce the frequency of replacements and eliminate the need for frequent shipments of spare parts, which helps lower the project’s overall carbon footprint. In contrast, mounts made from brittle plastics or non-standardized components are often discarded after a single use, adding to landfill waste and increasing replacement costs over time.

Retailers must also factor in vendor support for mounting accessories. A reputable ESL provider should offer detailed guidance on accessory compatibility, installation methods, and maintenance practices. In addition, the ability to source replacement parts quickly and at scale is vital for stores that experience high foot traffic or operate in extreme conditions. Poor vendor support can lead to delays, unscheduled maintenance, or even customer service disruptions, all of which degrade the ROI of the ESL investment.

Ultimately, a thorough and honest ROI analysis for ESL deployment requires a total-cost-of-ownership perspective. The value of ESLs is not measured solely in reduced paper label printing or dynamic pricing capabilities—it must also account for all underlying components that make those features possible, including the mounting systems. Retailers who adopt a short-sighted approach by cutting corners on accessories may save upfront but will inevitably pay more over time in the form of labor inefficiencies, damaged units, and lost operational uptime. By contrast, those who invest in high-quality, fit-for-purpose mounting solutions are more likely to realize the full potential of their ESL system and achieve sustainable ROI over the long term.

In conclusion, mounting solutions are not merely an accessory to ESL deployment—they are a strategic component that deserves detailed analysis, budget allocation, and thoughtful vendor selection. From material durability and craftsmanship to labor efficiency and environmental impact, mounting accessories touch every aspect of the ESL lifecycle. Retailers who understand this dynamic and incorporate it into their ROI models will be better positioned to justify their ESL investment, maximize performance, and avoid costly oversights. As the retail industry continues to digitize and automate, paying attention to the details—like mounting systems—is what separates successful digital transformation from costly experiments.

Why choose Smart Label Solutions™ as your ESL solution provider and partner

Smart Label Solutions™ is a solution driven, service minded company, and a world leading e-paper application provider with over 33 years of experience and excellence in the label industry. We’ve worked with some of the world’s largest retailers, and as a people-first company, we build trusting partnerships with our clients. Our electronic shelf label solution is tailored to suit your individual store scenario.

Get in touch with SLS today to get started with electronic shelf labels.